GUPTA LABORATORY

Laser Shockwave and High Velocity Impact Physics

Facilities

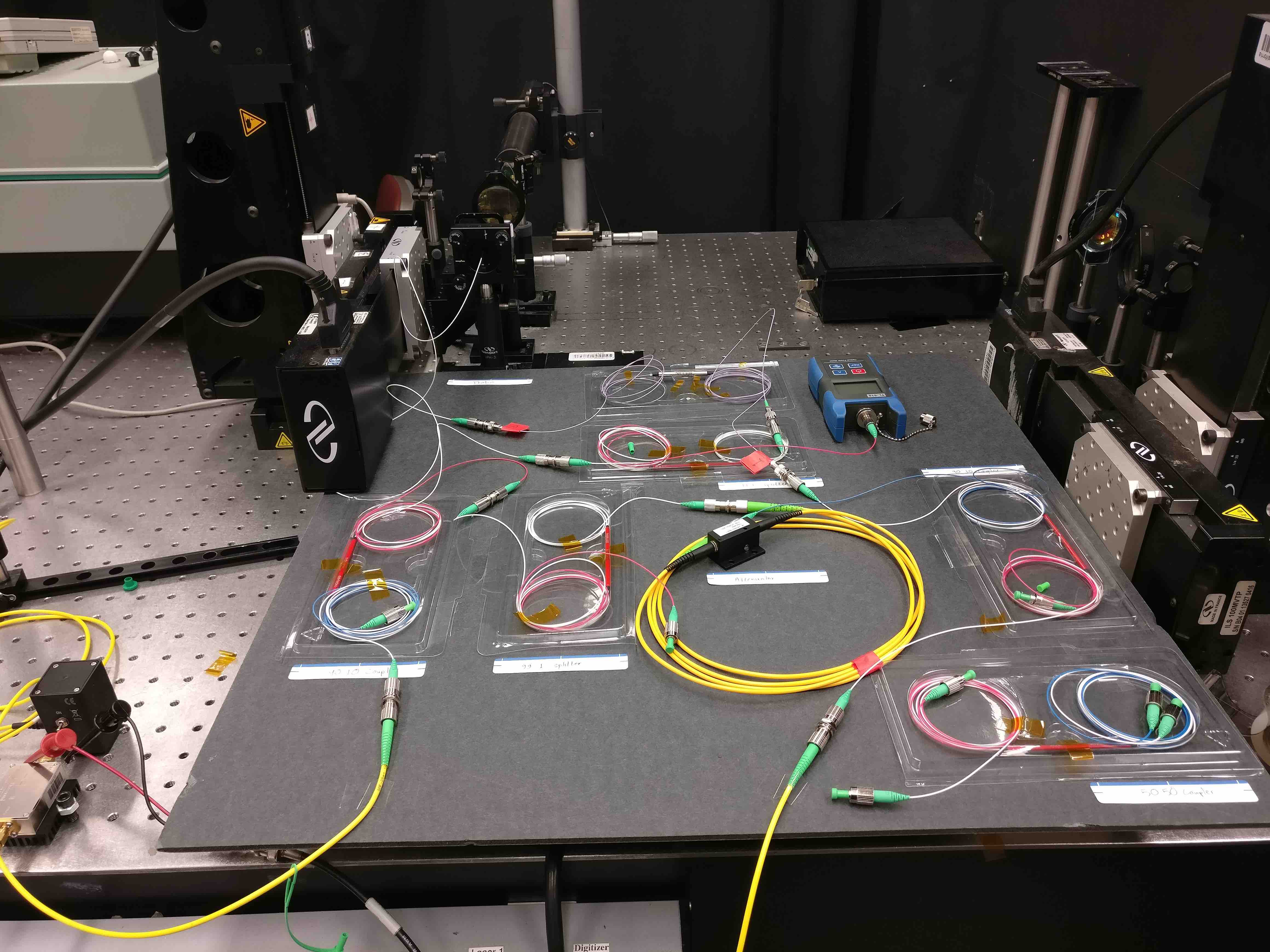

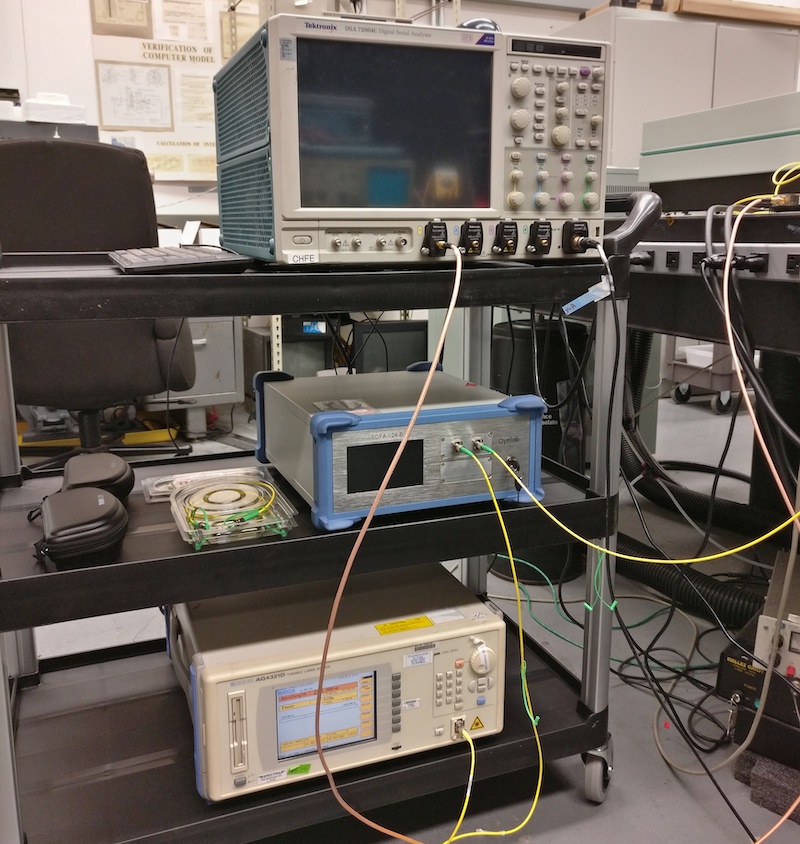

Fiber Optic Equipment

Optilab 40 mW laser diode with 10 kHz linewidth, Optilab EDFA laser amplifier, Tektronix 72004C oscilloscope

THORLABS fiber-optic components at 1550 nm wavelength: Couplers, splitters, circulator, GRIN collimators

THORLABS fiber-optic components at 1550 nm wavelength: Couplers, splitters, circulator, GRIN collimators

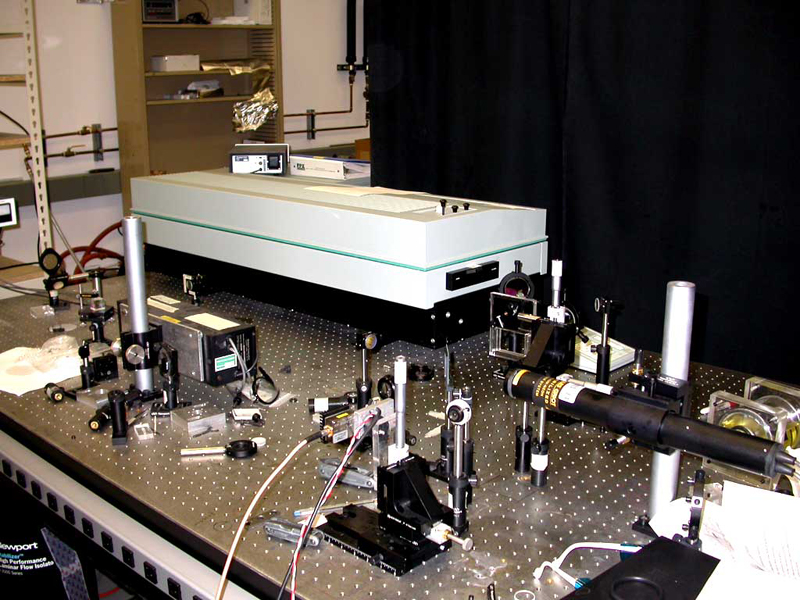

Neodymium:YAG Laser (High Power)

The Continuum Powerlite Series (Powerlite Precision Plus) in our lab provides high performance in a compact package. The Powerlites range from 550 mJ to 3 J at 1064 nm, again with harmonic options for 532 nm, 355 nm and 266 nm outputs. Pulsewidth is rated at 6 ns. The Powerlite Plus is a versatile laser available with injection seeding option, double pulse option (DPO), or the Beam Access Package.

- 30 µrads pointing stability, excellent long term stability

- Excellent beam quality, ideal for pumping OPO's

- Proven design - fewer component yet highest commercial performance

- 30 µrads pointing stability, excellent long term stability

- Excellent beam quality, ideal for pumping OPO's

- Proven design - fewer component yet highest commercial performance

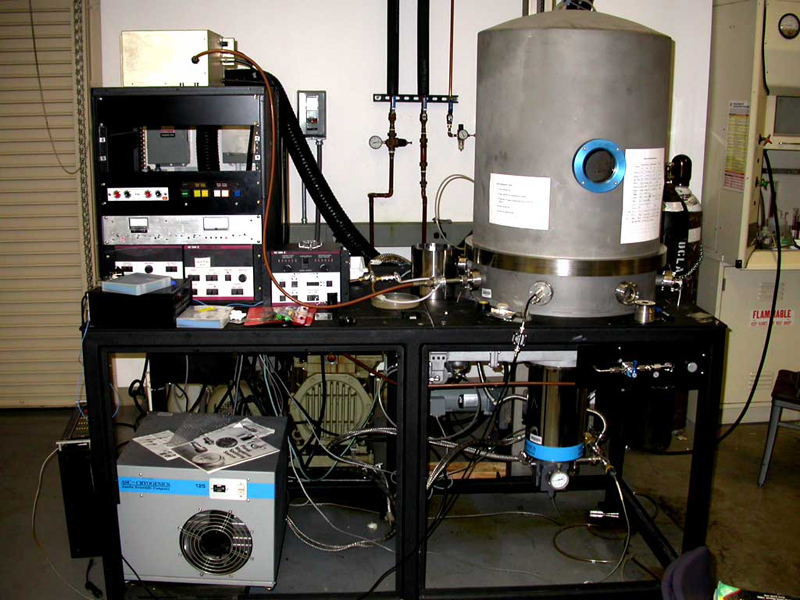

Magnetron Sputtering System

The purpose of the sputter deposition system is to deposit a uniform film of some material onto a substrate. This process is performed in an evacuated chamber, filled with argon (Ar) at some relatively low pressure. The sputtering guns are controlled by either a Radio Frequency (RF) power supply or a DC power supply. There are two identical guns in the system, located in the bottom rear of the chamber. The target, or the material to be deposited, is a disk of pure material mounted on top of one of the sputtering guns. When the power supply is turned on, a powerful magnetic field causes excited Ar ions to collide with the target surface, removing atoms of material. The atom then moves to the substrate where the film grows. The vacuum is created in the chamber by two pumps used in series. A mechanical pump brings the chamber to an appropriate starting pressure, then the cryopump brings the chamber to the appropriate pressure for the sputtering process. Substrates are placed deposition side down on the rotating tray in the middle of the chamber above the guns. There are many devices available for mounting different sized samples. If the thickness is critical, the in-situ quartz sensor is used to exactly monitor film thickness.

Microfilm Analysis Microscope

We have an analysis station where we are able to observe the structure of our samples via optical microscope. This station has been used in many of the laser spallation technique studies to determine the remaining structure of a microfilm and if it was delaminated.

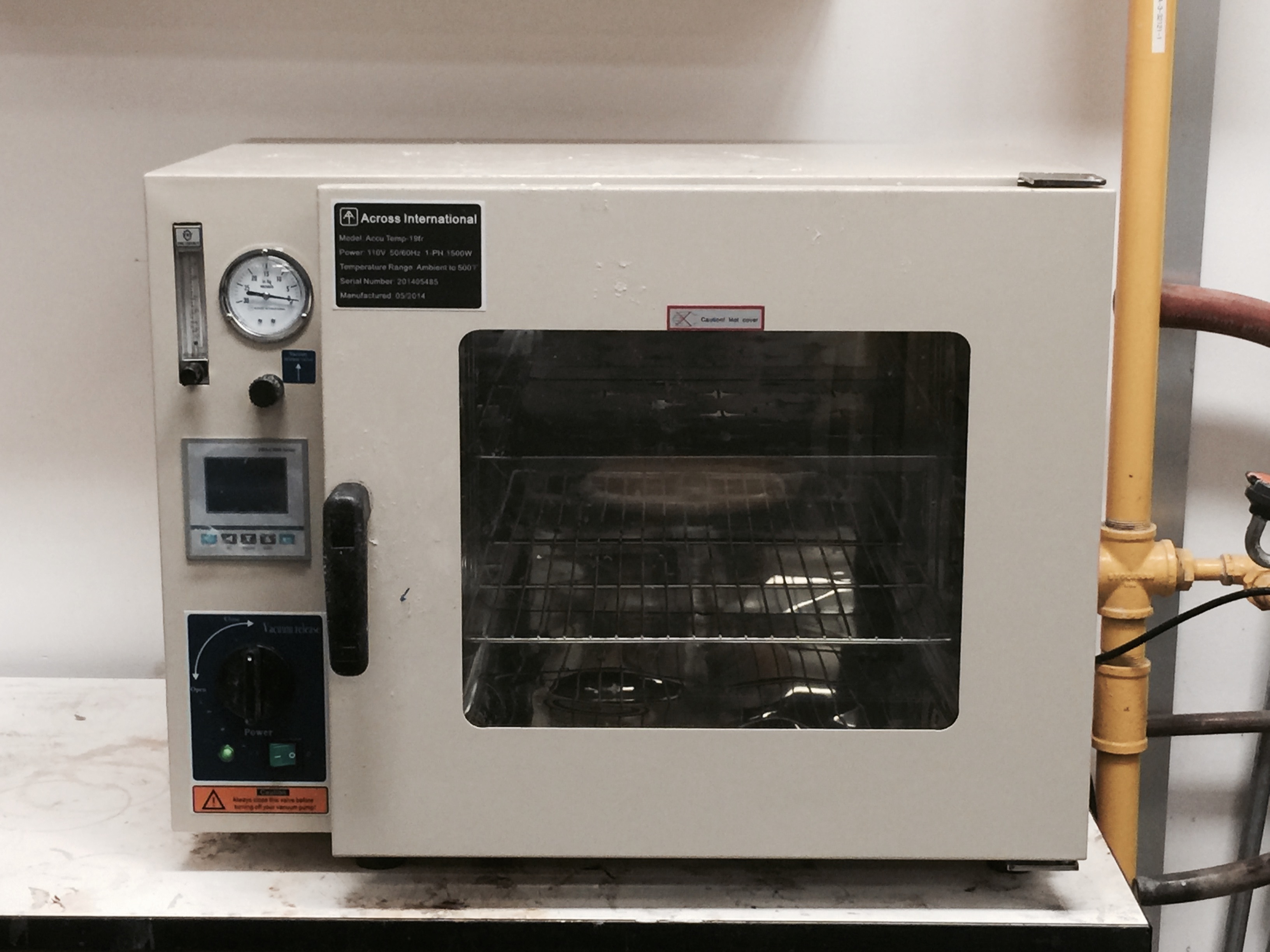

Vacuum Oven

This vacuum oven is capable of reaching temperatures of 570°C with programable accuracy for temperatures from room temperature up to it's maximum value. As well, this oven can go down to pressures of 500 µ/mTorr. This setup is ideal for curing our polymer samples.

Environmental Chamber

This is a self contained system that allows for a temperature range from 0°C to 94°C with a humidity range from 20% to 98%RH. This setup has been used to test degradation of composite joints in an accelerated test environment.